Northern Lights has a fleet of 12 units to accommodate our customer’s needs in five shops across the Midwest and Texas. We have single drum, split drum, and dual drum setups. Standardly, for sweet wells we run a .108” or .125” carbon wire, which as a company, we prefer for it’s workability, longevity, and strength. In highly corrosive fields with high CO2 or H2S we run a .108” or .125” GD31-6MO wire that can run in the harshest of corrosive environments. Depending on the clients needs, we can run in any downhole environment.

Our standard lubricators range from 2 7/8” to 3 ½” which allows us to run in all sizes of tubing. The lubricators have a pressure rating ranging from 3000 psi up to 10,000 psi. Standard lubricator length is 24 feet of lubricator plus pump-tee and BOP, giving NLEC the capability of hiding up to 27’ of tools minimum. This comes in handy when needing to put on 5 x 5’ tungsten stems to run a flowing log in high flow conditions. On top of that, each truck is equipped with lubricator pups to hide even more if needed for fishing purposes.

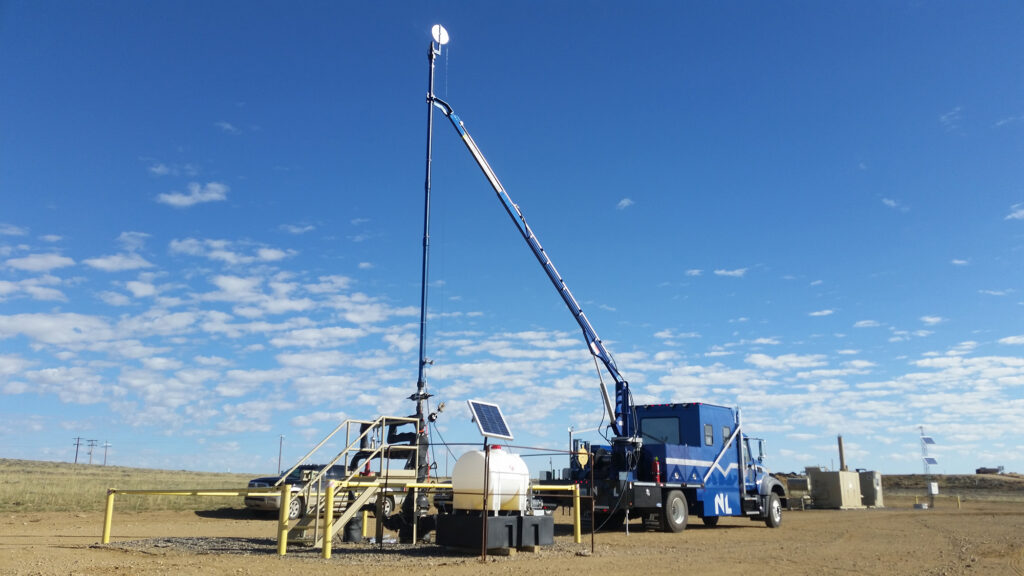

With our quick rig setup, NLEC boasts an efficiency that is unmatched in our industry. While maintaining safety, our crews can efficiently rig up multiple times per day, or rig up to any type of workover rig, snubbing unit, or drilling rig.

Each unit comes with all the standard slickline tools, from overshots, grapples, broaches, gauge rings, impression blocks, etc. In addition, each area stocks specialty tools that are available at the request of the client, ranging from all types plugs (tubing/profile), bulldog spears for specialty internal fishing, single shot to multi-shot perforators, and BHP’s up to 16000psi rating.